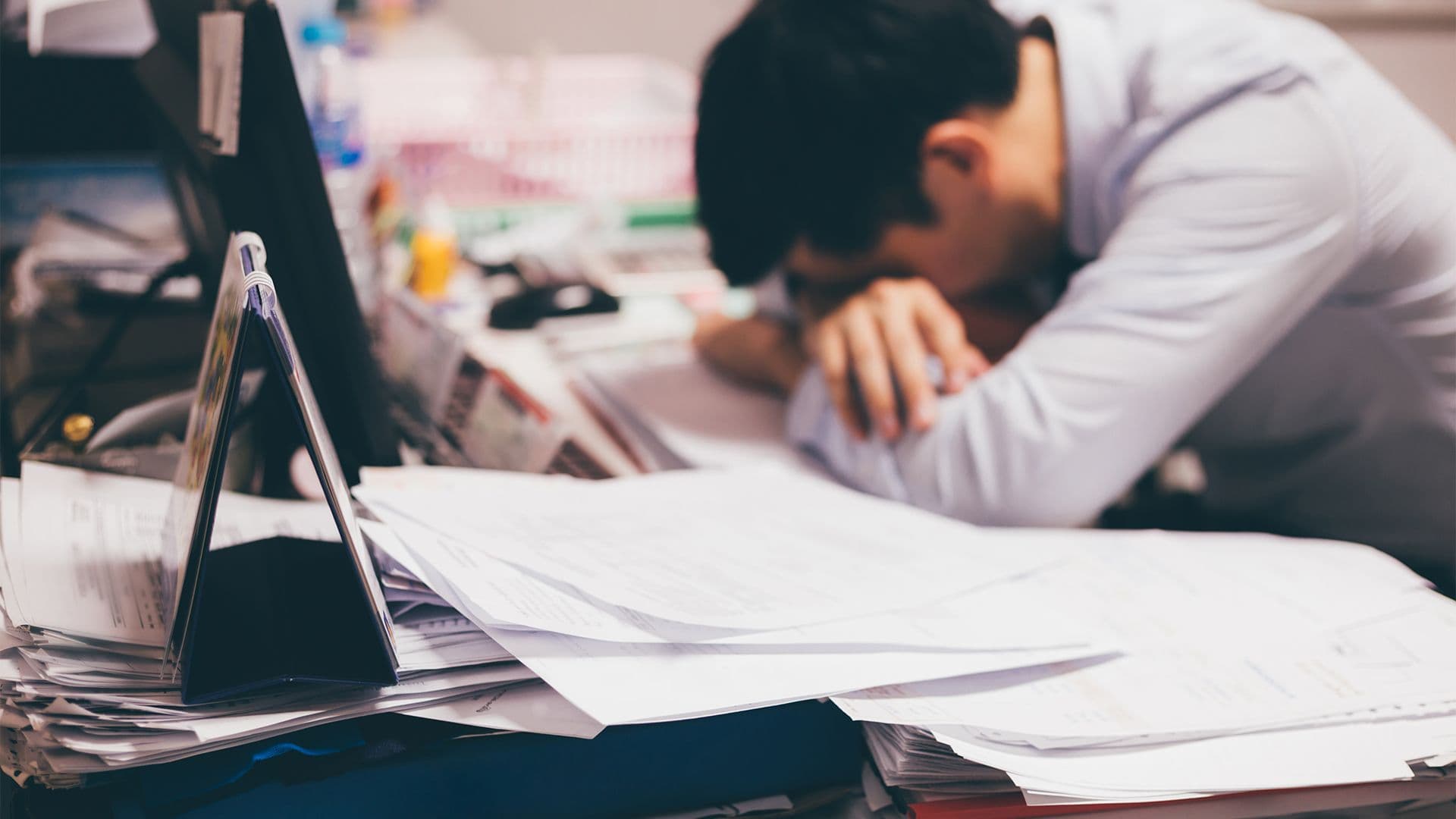

There’s no doubt that paper costs money. The worst part is, it doesn’t even last. Paper documents are easily lost, destroyed, and quickly become out of date; requiring you to constantly purchase more and more paper. For the paperwork and documents you do want to keep, you’ll need to store them somewhere, taking up valuable space.

This goes directly against the principles of lean manufacturing and this ultimately hurts your bottom line. Not to mention that continued mass consumption of paper is not doing any favours for the environment.

According to the University of Southern Indiana, 1 billion trees worth of paper are thrown away each year in the United States alone. This means that despite the vast amounts of money spent on paper, we end up throwing away a large portion of it every year. What a waste!

When less costly, more efficient, and environmentally friendly solutions are available, we have to ask ourselves: Why would we not digitize our operations and implement paperless solutions?

Although we’ll focus on the benefits of paperless manufacturing, many of the concepts are easily transferable to other industries that are looking to reduce costs, reduce mismanaged documents, reduce their environmental footprint, increase data accuracy, and increase company strength through lean principles.

Going Lean by Going Paperless

Regardless of your industry, reducing paper usage will generate positive outcomes and cut at your company's expenditures. As we’ve explored in a previous blog post, not only is paper expensive each year, it is also costly to store and retrieve.

Think about a very likely scenario for a minute. You have a talented audit team of 3 making $20 per hour each. Now, this team spends on average, 1 hour per day each handling paper. Updating, printing, copying, filing, looking up, etc. In this example, you are investing a minimum of 3 hours or $60/day on just managing the paper audits. Not a huge number until you look at it over a year - $15,600. -

5 Benefits of Paperless Manufacturing Audits

Reducing paper usage is the first step to cutting waste and adopting lean manufacturing principles. Implementing paperless solutions such as VKS digital work instructions, digital audits, and data collection will have your company spending less and wasting less.

Waste in manufacturing is often referred to as ‘Muda’, which is a Japanese term for ‘futility, uselessness, and wastefulness’. When discussing the impact of paper on manufacturers, it’s easy to see that paper is wasteful and in some modern industries, quite useless compared to the paperless solutions of the current era.

There are 8 main categories of Muda, all of which can be exacerbated by paper-driven processes or mitigated by utilizing paperless manufacturing software such as VKS work instructions. Below we briefly touch on each Muda, and how reducing paper usage can benefit your operations and business.

1. Defects In Production

A sheet of paper is only accessible to one person at a time. You could print out multiple copies for each employee, but then anything employees add to their sheets of paper is not quickly accessible to the team. When auditing and evaluating your process and equipment for defects, you need all pertinent information to be quickly available to all employees.

By going paperless, data collection and document sharing happen in real-time, allowing for fast awareness and quick responses to quality issues or defects. With VKS, digital reports are easily found with the integrated report search filter. No more lengthy searches that cost you money.

Just digitizing documents and reducing paper usage leads to faster, more accessible, and more accurate mitigation of defects in your production line.

2. Overproduction

Besides printing and copying too many sheets of paper, unregulated documentation leads to unreliable information, which in turn leads to overproduction in reporting and potentially overproduction of a product.

Through paperless manufacturing software like VKS, reliable production and capacity planning are based on true demand (JIT) via virtual connections with an ERP or direct to customer. The concept of JIT, or Just-In-Time manufacturing, is employed to accurately forecast product demands based on advanced analytics. By utilizing this method, product and inventory needs become predictable and less wasteful.

By reducing paper usage and implementing paperless solutions, overproduction can be avoided with regulated documentation and accurate data.

3. Waiting

Again, the transfer of information and data through paper records and documents is slow. Your company can speed up the flow of information by simply switching to a digital solution that will store, record, track, and analyze the data for you.

Additionally, by implementing paperless manufacturing solutions, live production progress monitoring becomes a reality. This means that knowledge about your assembly line is available in real-time, enabling managers to adjust resources for line balancing through increased line visibility. No more waiting for knowledge and data.

4. Not Utilizing Talent

As we’ve seen, managing paper records requires time and energy. Employees that have the skills to provide greater value are stuck being underutilized by sorting paper records.

By reducing paper usage and adopting paperless manufacturing solutions, you are redistributing talents to more productive areas in your company. This allows employees to grow in their professional development and improves labour flexibility, adding more value to your company.

5. Transportation

Paper reports will not analyze transportation inefficiencies in real-time. By utilizing multi-functional paperless solutions that allow drivers, transporters, and management to coordinate and get up to the minute data, you will gain new insight into your company’s operations. This enables you to constantly improve and increase transportation productivity and efficiency.

6. Inventory Excess

If paper records are up to date and stored properly, then having a comprehensive understanding of your inventory is still a challenge. If the paperwork is not filed correctly, it's a nightmare.

By reducing paper usage and switching to paperless manufacturing solutions, your company’s inventory data will be accessible, fast, and accurate. You will gain real-time awareness of your project materials and also what is needed, when it’s needed, and where it’s needed. This greatly reduces non-value-added inventory expenses.

7. Motion Waste

While using paper for work instructions, employees will constantly have to stop what they're doing, pick up the paper, review, and set it down… multiple times during an assembly process.

With our paperless work instructions software, employees have access to hands-free digital instructions that will progress as they perform their tasks. Reviewing work instructions becomes a whole lot faster.

Additionally, through advanced data collection, VKS will enable managers to quickly highlight and isolate wasted motion in processes on the shop floor. By providing better visibility to production flow, your company will have the tools to continuously improve upon its productivity and efficiency.

8. Excess Processing

Printed work instructions or documents are static.. until you print new ones. This constant re-printing of documents gets tiresome and costly. Before paperless manufacturing, companies would be stuck with either constantly re-printing documents or using inaccurate records that lead to inefficiencies and process dissonance.

With either of these two methods, the company is over-processing.

By reducing paper usage and implementing digital work instruction solutions, operators and employees will always have the current and most effective processes to follow. This greatly reduces inefficient work and non-value added processing.

Paper usage is also detrimental to the environment, especially considering that a considerable amount of paper we use is thrown away - and hopefully recycled. Here is a brief list of how paper production and waste is not helpful to the environment.

-

Deforestation

- Paper demand worldwide has grown 400% in the last 40 years, demanding 35% of all harvested trees be used for paper production.

- Globally, nearly 4 billion trees are harvested annually for use in paper manufacturing.

-

Water Usage and Pollution

- Paper production wastewater, containing dissolved organic and inorganic material, contaminates lakes and rivers with chlorates and metals including lead.

- 17,000 gallons of fresh water are required to manufacture 1 ton of paper. This is more than what is required by any other industry to produce 1 ton of finished product.

-

Air Pollution

- Paper manufacturing facilities emit nitrogen dioxide, sulfur dioxide and carbon dioxide, all contributors to acid rain and climate change.

-

Energy

- The worldwide paper industry consumes a huge amount of energy, accounting for 4% of the world’s energy use alone.

Given these facts, going paperless can have far-reaching positive impacts on all aspects of the environment. Reducing deforestation and helping provide clean air and water is no simple task. But by reducing paper usage and implementing paperless manufacturing solutions, companies can progress to a leaner and greener world.

With a powerful paperless solution like VKS, the industry has an enormous opportunity to finally rid itself of the liability, cost, and inefficiencies associated with paper-driven processes. By going paperless, innovative and lean oriented leaders will understand the clear return on investment for their companies as well as for the environment.

With contributions from Shannon Bennett.