VKS Lite

Capture knowledge, standardize work, and boost productivity.

VKS EDGE

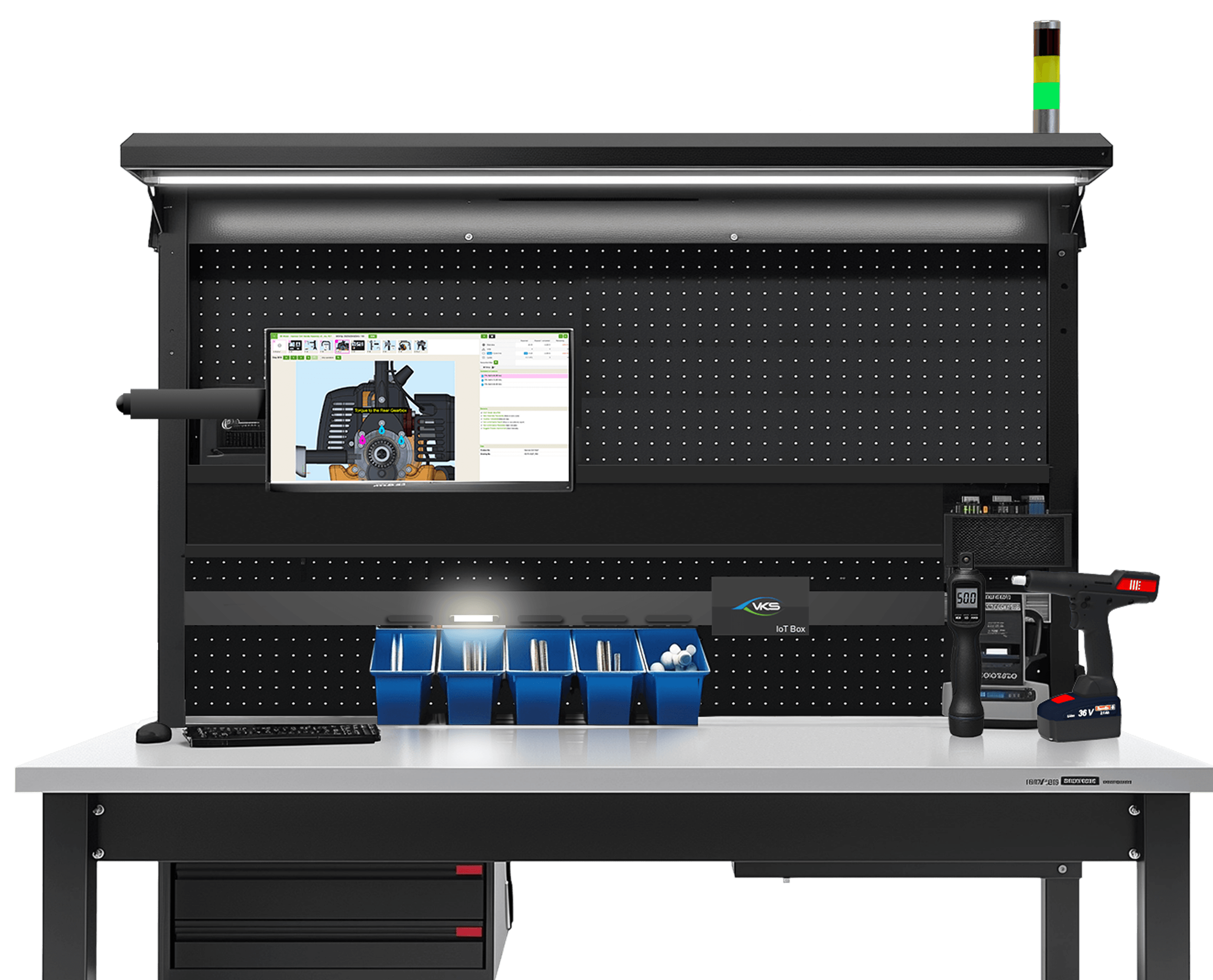

Connect with torque tools, PLCs, sensors, vision systems and more to automate interactions and data collection in your manufacturing environment.

Transform your shop floor into a connected, data-driven ecosystem with VKS Edge.

Each integration creates an efficient, error-proof, and intelligent production environment.

Transform your shop floor into a connected, data-driven ecosystem with VKS Edge. Each integration creates an efficient, error-proof, and intelligent production environment.

Push required settings and collect torque results from assembly tools.

Integrate your work instructions with torque tools to eliminate the risk of human error while boosting your quality data collection.

ToolConect IoT pushes Pset parameters directly to your tools, captures/validates torque values, and auto-advances your work instructions, creating a streamlined, automated, and collaborative work environment.

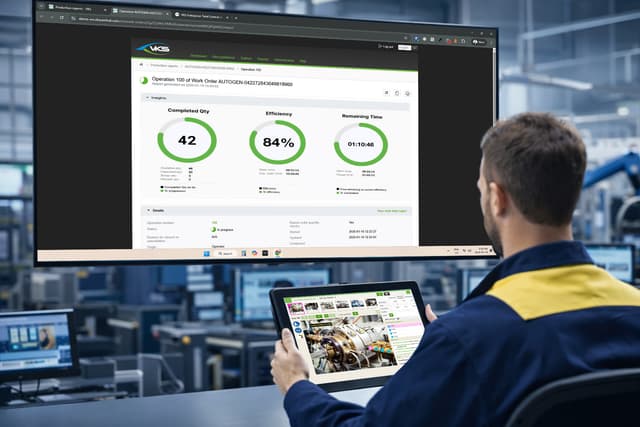

Take digital integration further by integrating your work instructions with your manufacturing environment and bridge the gap between the physical and the digital worlds.

IO Connect gives you the ability to both activate and monitor your manufacturing environment directly from your digital work instructions.

Empower your work instructions to communicate directly with databases and database-driven equipment through the power of VKS DataConnect.

The solution enables seamless, real-time information exchange while maintaining accurate records and streamlining worker actions on the shop floor.

Reach out to one of our industry experts and take your operations to the next level!

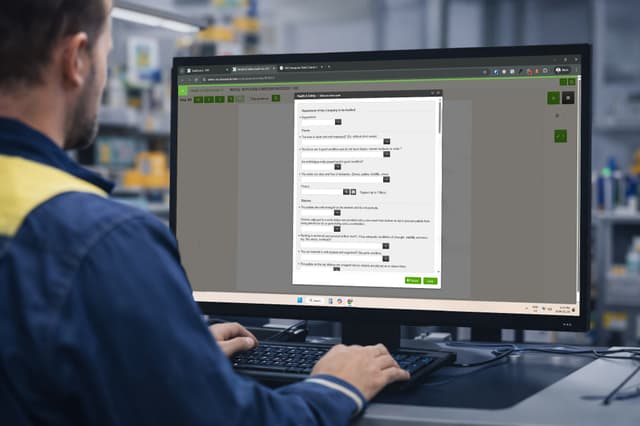

Capture knowledge, standardize work, and boost productivity.

Standardize data collection and built-in quality control.

Connect people, processes, and systems in real time.

.jpg&w=640&q=75)

Ensure precision at every step with tool and device integration.

Ensure precision at every step with tool and device integration.

Learn how easy it is to transform into a digital factory. See an overview of how VKS work instructions works!

Explore and learnExplore the latest trends, best practices, and insights shaping smart manufacturing. Stay up to date with expert tips on using VKS software effectively and get the latest updates on our newest releases.

Check it out!Discover real-world case studies and learn how customers tailor VKS Work Instructions to their facility! Some customers have seen an increase in productivity by 75%!

Find out how!