VKS Lite

Capture knowledge, standardize work, and boost productivity.

VKS PRO

VKS Pro enables you to create electronic work instructions that guide workers while collecting valuable data. Gain key insights and guarantee quality at every step of your manufacturing process.

VKS Pro empowers your team to collect real-time quality and production data, like serial numbers and cycle times, providing actionable insights for continuous improvement and error-proofing.

Create responsive instructions that dynamically guide workers based on the needs of the process.

Automatically monitor key metrics like cycle time, efficiency, and first-pass yield in real time.

Collect in-process data like serial numbers, quality checklists, and more.

Automatically gather data from connected tools to eliminate manual entry errors and guarantee data accuracy.

Ensure quality is built into every process by integrating standardized instructions, data collection, and quality checkpoints. VKS Pro empowers you to capture key production and quality data while interactively error-proofing your process.

Direct your team with pictures, videos, and annotations to engage workers and eliminate errors.

Use checklists and forms to prompt confirmations and display inspections based on frequency, time, or events.

Capture measurements, serial numbers, part numbers, signatures, and even perform automatic mathematical equations.

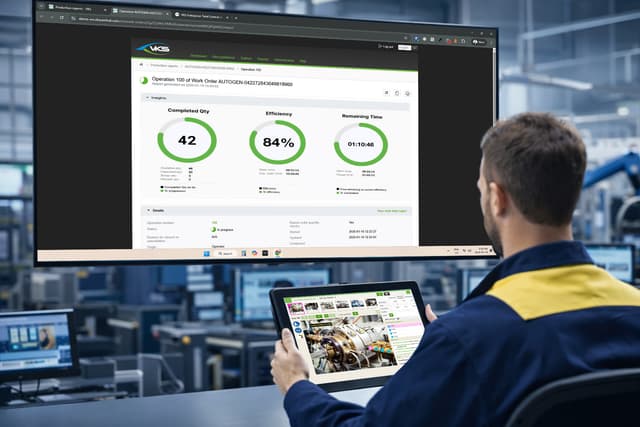

VKS automatically tracks productivity in real-time by monitoring time and quantity metrics. This provides advanced insights into performance, predicts remaining time, and gives you immediate visibility into efficiency.

VKS Pro tracks cycle time, production time, and key process metrics to calculate efficiency and predict remaining times.

VKS Pro ensures complete production traceability by monitoring completed units, scrap, rework quantities, and First Pass Yield rates.

![]() "VKS has fostered quality through the use of custom forms that are embedded in each station's guidebooks, asking operators to inspect a few critical quality features of the prior process before beginning work in their station."

"VKS has fostered quality through the use of custom forms that are embedded in each station's guidebooks, asking operators to inspect a few critical quality features of the prior process before beginning work in their station."

Brunswick Boat Group - Brunswick Boat Group

![]() "Now the system doesn't let our employees make mistakes and proceed. This is incredibly important to us."

"Now the system doesn't let our employees make mistakes and proceed. This is incredibly important to us."

Republic Manufacturing - Republic Manufacturing

![]() "We started using VKS Smart Forms to trigger at certain points in the guidebooks. This informs our materials supervisor to send materials ahead of time."

"We started using VKS Smart Forms to trigger at certain points in the guidebooks. This informs our materials supervisor to send materials ahead of time."

KONE - KONE

![]() "Now the system doesn't let our employees make mistakes and proceed. This is incredibly important to us."

"Now the system doesn't let our employees make mistakes and proceed. This is incredibly important to us."

Republic Manufacturing - Republic Manufacturing

![]() "We started using VKS Smart Forms to trigger at certain points in the guidebooks. This informs our materials supervisor to send materials ahead of time."

"We started using VKS Smart Forms to trigger at certain points in the guidebooks. This informs our materials supervisor to send materials ahead of time."

KONE - KONE

VKS Pro allows you to error-proof instructions at every step. Adjust to new conditions, instantly trigger digital forms for data capture, and send real-time notifications to manage deviations and non-conformances faster.

Automatically open digital forms, trigger workflows, and navigate to specific steps based on user inputs or automated events.

Automatically notify teams of key events, including work instruction changes, non-conformances, and performance.

Empower workers to report and find solutions faster with non-conformance reports and resolution forms.

Observe real-time work order status and operation data in VKS Pro. Easily access KPIs and export comprehensive reports, gaining a clear perspective on product flow and team performance across your factory floor.

Monitor the current progress, activity, available units, and completed units of each work order/operation.

Predict efficiency metrics and remaining time while viewing quality metrics, cycle times, set-up times, and more.

See every interaction with a smart form or checklist to see process confirmations, serial numbers, production data, and SPC charts.

Track lot numbers, quantities, date/time, users, locations, and more to create complete history records.

Clear, consistent, and engaging instructions for all teams.

Collect in-process data and validations to ensure quality at every step

Streamline activities with connected devices and tools.

Empower feedback and data-driven enhancements.

Gather real-time insights from your shop floor.

Leverage the rule engine to create responsive workflows.

Reach out to one of our industry experts and take your operations to the next level!

Capture knowledge, standardize work, and boost productivity.

Standardize data collection and built-in quality control.

Standardize data collection and built-in quality control.

Connect people, processes, and systems in real time.

.jpg&w=640&q=75)

Ensure precision at every step with tool and device integration.

Learn how easy it is to transform into a digital factory. See an overview of how VKS work instructions works!

Explore and learnExplore the latest trends, best practices, and insights shaping smart manufacturing. Stay up to date with expert tips on using VKS software effectively and get the latest updates on our newest releases.

Check it out!Discover real-world case studies and learn how customers tailor VKS Work Instructions to their facility! Some customers have seen an increase in productivity by 75%!

Find out how!