Work Instruction Software

Learn how easy it is to transform into a digital factory. See an overview of how VKS work instructions works!

Explore and learnBlog

Explore the latest trends, best practices, and insights shaping smart manufacturing. Stay up to date with expert tips on using VKS software effectively and get the latest updates on our newest releases.

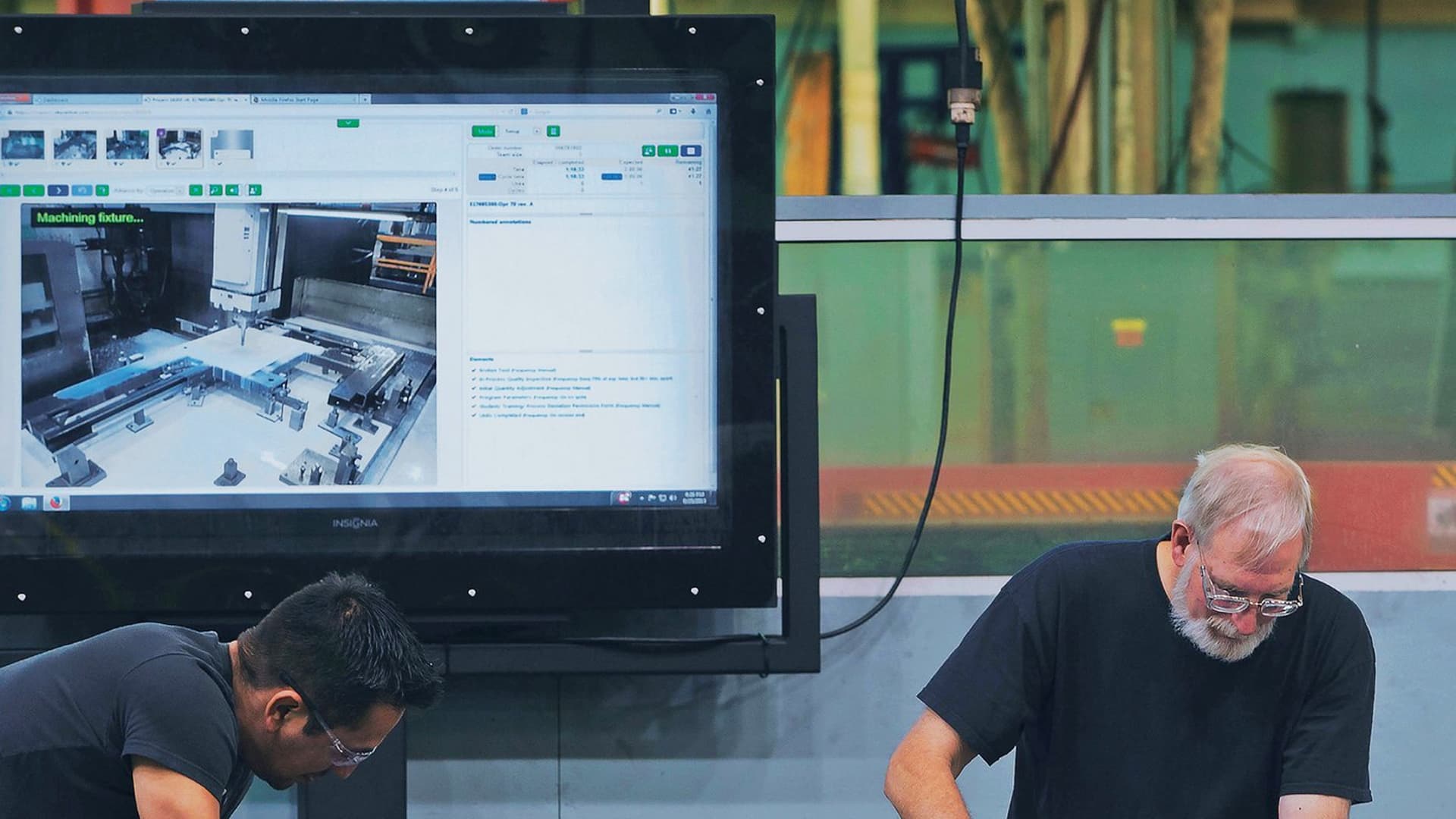

Check it out!Customer Success Stories

Discover real-world case studies and learn how customers tailor VKS Work Instructions to their facility! Some customers have seen an increase in productivity by 75%!

Find out how!