Kanban

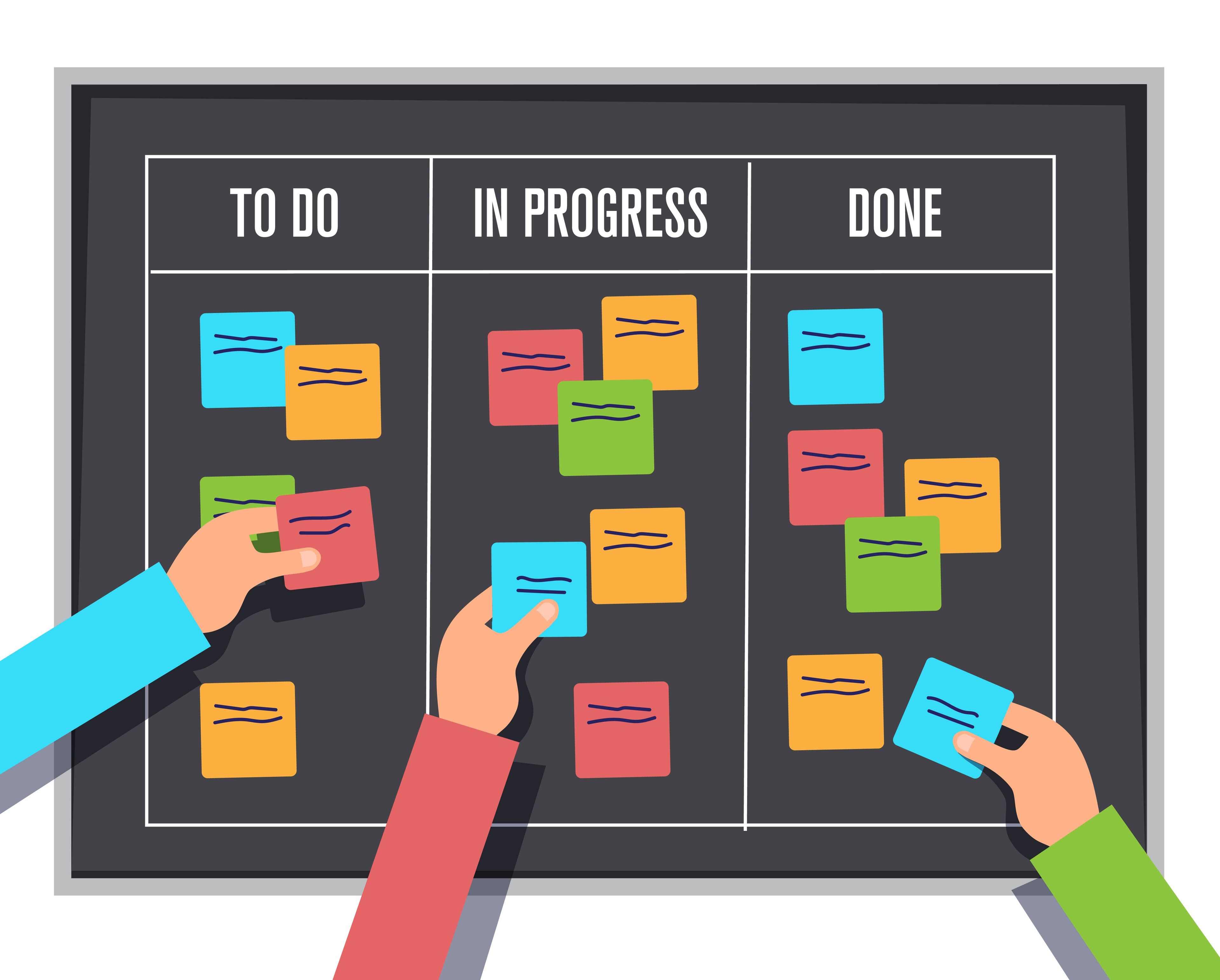

Kanban is a visual workflow management system that involves moving tasks (represented by cards) between three columns: jobs to be done, works in progress, and completed tasks. Translated from the original Japanese, kanban means “billboard” because the cards serve as clear visual indicators of continuous workflow.

Key Takeaways

Used to identify bottlenecks in workflow

Associated with JIT production

Visual planning for project management

Both lean and agile, originated with TPS

What Is Kanban?

Kanban is a management control system that eliminates bottlenecks in workflow. Benefits of using a kanban board include:

- Better communication through definable tasks

- Aligned expectations on scope and task requirements

- Ability to smooth over bottlenecks

- Fewer disruptions/less downtime

- Transparency in tasks

- Better consistency with deliverables

Kanban does not work on its own. Kanban is a stylistic way of looking at other systems at play via visual cards.

By saying this we mean that kanban isn’t a standalone planning exercise – there is no ideal “kanban goal” like there is in, say, kaizen (continuous improvement).

Example: Popular management tools like Trello, Asana, or Google calendar are good examples of kanban-style tools because without any projects to fill these calendar and task tracking programs with, they serve no use in themselves. After all, what’s the point of a To-Do list if there’s nothing to put on it?

Where Did Kanban Come From?

Kanban is a Japanese term that translates to “billboard” because the visual cards present immediately digestible information just like billboards do. It was created as a management tool for the Toyota Production System in the 1940s, alongside the Just-In-Time production system.

The JIT system changed the standards of production by relying upon a “pull” system rather than a “push” system. This means that instead of “pushing” work orders through production in order to stockpile a supply of product, team leads began to “pull” orders through production only once demand was established.

Kaban works hand-in-hand with JIT production because it provides a real-time visual indicator of the entire workflow of the factory.

Kanban has continued to become a useful resource within the current knowledge economy. Originally, kanban organized the movement of physical product resources. Nowadays, with so much industry occurring in the realm of the knowledge economy, kanban boards track less concrete (but still important!) things such as deadlines, expectations, and technical reporting.

How To Set Up a Kanban Board

There are three columns in a Kanban layout, each with a different heading. From left to right, the first is To Do, the second is Doing, and the third is Done.

It’s simple enough that you don’t need any special software or even an analytical eye; you can set one up right now using a whiteboard and some sticky notes.

On each sticky note, write a single task, and try to include as little detail as possible. If there is too much to write on a single sticky note, consider splitting the task up into smaller achievable parts.

As tasks are completed by your team, move the sticky notes with those tasks to the next column on the right. This will give a clear visual indication of how much is actually accomplished versus how much needs to still be done.

Pro Tip

Don’t try to get tricky! A kanban board will fall apart quick if you try to combine tasks into multi-step projects for a single sticky note. This is because even if your team is continually working away, achieving small wins, they still don’t see the sticky note progressing through the process planning board and they will feel overwhelmed and like their work is not accomplishing anything over time.

The 6 Rules of Kanban

There are six basic rules for implementing a successful kanban board.

1. Visualize workflow

This is the first step of setting up a kanban board so it should be about the actual state of workflow, not the ideal state you hope it will become. This will help you to understand how many items are in the backlog.

2. Limit WIP

Once you have all the jobs written down on the cards, start moving some over to the works in progress column. Now, your team probably already has a lot on the go, so set a strict limit on the maximum number of cards that can be in the second column. The reasoning behind this is your team will feel overwhelmed if there are too many jobs on the go, and their energy and skills will be diluted as they attempt to work on all of them.

3. Manage flow

Remember to manage the work, and not the people. You’re not the only one using the kanban board, it’s for everyone on your team to use. Micromanaging your employees only will add to frustration and overexertion.

4. Define process policies

As you continue to use your kanban board, gradually set up best practices and SOPs based on the things that end up working for your team. Maybe things have been smooth enough that you can increase the limit on the WIP column.

5. Implement feedback loops

Ideally, you want to implement feedback loops that will keep the ball rolling. An example of this is having daily standup meetings so everyone can inform the others about any cards switching between columns. This is also a great practice to jumpstart continuous improvement, as workflow keeps stemming from the jobs to be done column.

6. Improve collaboratively, evolve experimentally

Same as with implementing any SOPs, you want to improve your unique kanban board with the input of all your team members so that it works best for you. You still can (and should) be experimental by trying out different SOPs or practices, but keep those experiments on a tight leash until everyone has had a chance to give their final input.

The Agile Perspective

Kanban is a part of the lean manufacturing philosophy, and it also has been adopted by the newer Agile framework. Kanban is more attributed to the former (lean), while something called “scrum” is attributed to the latter (Agile). However, they both can be used for either underlying purpose.

Kanban works hand-in-hand with these methodologies because it mirrors the philosophy of continuous improvement (kaizen). By mapping the flow of tasks being done, team members get to see the continuity of their daily tasks and how they fit into the team structure.

This is also why that third column of completed tasks is so necessary! But for real, isn’t the best part of completing something on your daily to-do list seeing it crossed off and knowing you don’t need to worry about it any longer?

What’s The Difference Between Kanban & Scrum?

Scrum and Kanban are two styles of task management that are both derived from lean and agile methodologies.

Scrum is more timeline-driven and focuses on incremental success using short-term goalposts (usually between 1 and 4 weeks).

Kanban is more about visualizing the system flow as a whole and shifting priorities as different phases of work progress.

Because the two practices have slightly different scopes, they are often used in tandem or on an as-needed basis.

Can Kanban Be Digitized?

Yes… but the real question is should it be?

Like all things that can be digitized to eliminate paper dependence, Kanban can be uploaded into a software system. The most common way this occurs is in an ERP (enterprise resource planning) system, which is a back-end resource planning and analytics platform. If this works for your organization then that’s perfectly alright to use.

However, one big issue with integrating kanban into your back-end system is that it’s hidden away in the back-end. The biggest benefits of using a kanban system is that it is visual, extremely accessible, and frequently referenced.

Therefore, the best possible place to set up your kanban board is on an empty wall in a common office meeting space. There’s just something about seeing the brightly colored sticky notes in an organized system every time you walk by that helps remind you of workflow status. It’s also helpful that the board is physically present because moving a sticky note from one column to the next can be much more validating and satisfying for task completion.

However you decide to use your kanban system, make sure that it doesn’t get hidden away somewhere and forgotten; the most effective kanban board is one that is easy to see and interact with.