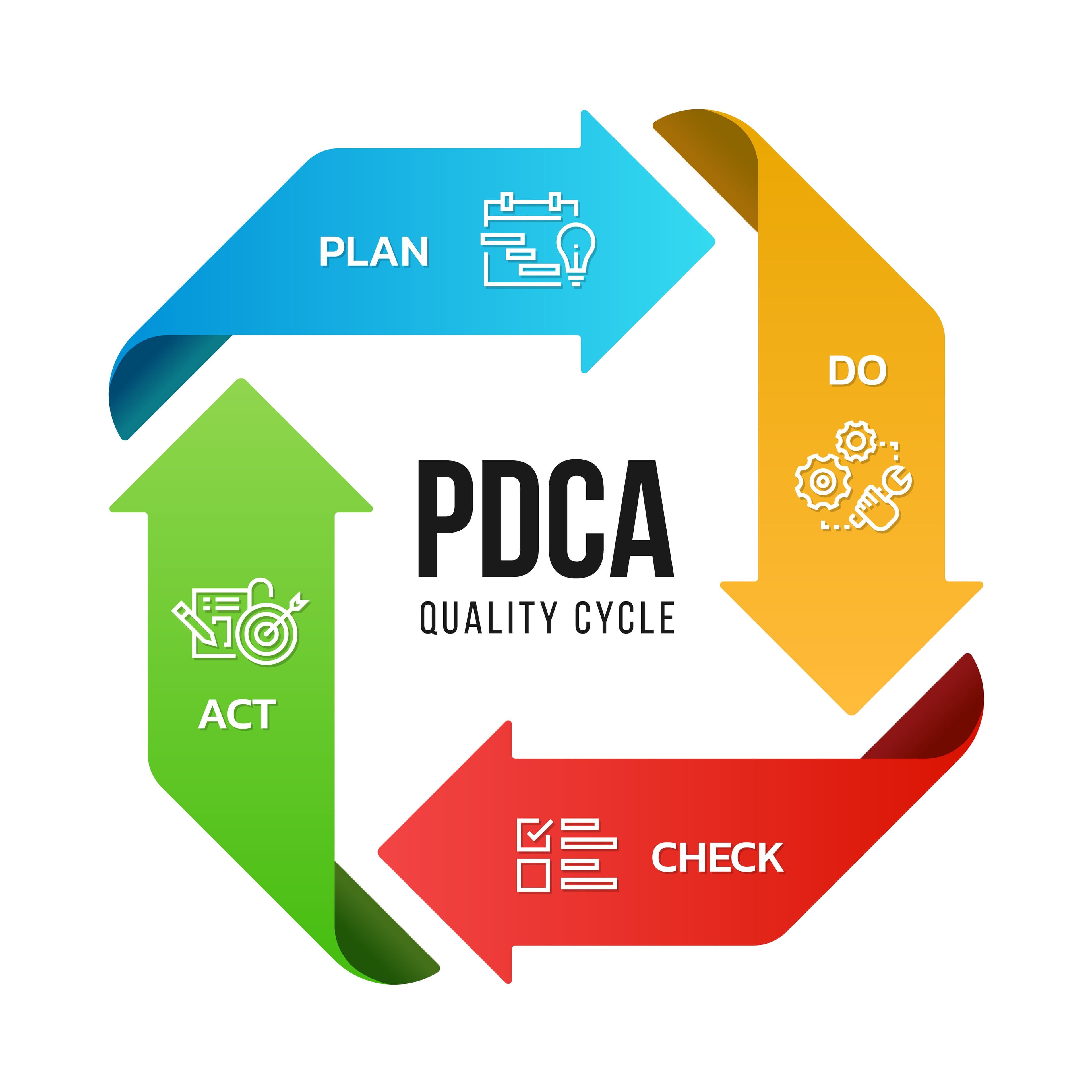

PDCA Cycle

A staple of any variation of institutional quality control methodology, the PDCA Cycle is a simple yet effective tool to plan and differentiate the steps of continuous improvement on a per-project basis. The PDCA Cycle is an iterative tool that is commonly used in the Six Sigma and Total Quality Management business philosophies.

Key Takeaways

Also known as the Plan-Do-Study-Act, Deming, or Shewhart cycles

4 steps: Plan, Do, Check, & Act

Meant to spur kaizen (continuous improvement) with each closed PDCA loop

It’s easy to say that your team emphasizes continuous improvement, but it’s harder to implement over time. The PDCA cycle helps break down kaizen into four manageable areas that can help guide a workforce towards a cyclical pattern of improvement.

Historical Origins of the PDCA Cycle's Variations

The first instance of the PDCA cycle is somewhat difficult to pinpoint. Most historians credit the cycle to William Edwards Deming, a prolific statistician and innovative management leader of the mid-20th century. Deming got inspiration from his mentor, Walter A. Shewhart, initially coining the process as the “Shewhart Cycle.” Over time, it became known as the PDSA (Plan-Do-Study-Act) Cycle, and sometimes as the “Deming wheel”.

But the origins of this cyclical process go back even further, to the scientific method developed by Sir Francis Bacon, which emphasized testing a hypothesis through systematic experimentation and logical conclusions.

Pro Tip

Some people like to reference this technique as the OPDCA Cycle, where O stands for “observing” the current situation. Managers that prefer this acronym like to take a longer time and a deeper look at the current situation at hand. The OPDCA version is optimal for companies that have undergone several cycles of the PDCA method for a specific issue, yet have not achieved expected improvement effects. There is a high possibility that some key factor in the production process has been missed, and observation allows for a more dedicated examination of the problem before any testing or organizational changes occur.

What Does PDCA Stand For?

The PDCA cycle – or whichever related acronym is your favorite – typically has four stages of development:

Step 1: Plan

You wouldn’t begin a scientific experiment without outlining your process, hypothesis, required materials, and introductory research, would you?

So when you’re aiming to fix or improve a critical production process, it’s only prudent to outline your full plan of attack before fiddling with any extraneous variables. Your planning stage should be fully fleshed out with as much detail as possible so that you have a map of options from which to choose at other critical stages of the PDCA cycle.

A good scientist leaves nothing to chance; a good manager accounts for every possibility to adapt quickly and lessen waste.

Step 2: Do

One of the most common errors leaders commit when implementing the PDCA cycle is over-emphasizing the “Doing” portion of the process. Even though it is a very enticing, active step, implementing change (i.e. “doing”) should be of secondary importance to your planning stage.

The reason why this step should be smaller than you would expect is that every plan of action used in this stage must be previously established in planning.

Doing is merely the extension of the planning process.

Think of your PDCA cycle like a textbook essay – in your first paragraph, you introduce the concepts you want to address, including the main topic or hypothesis. Then, in the second paragraph, you expand upon those concepts you brought up in the introduction. If you were reading an essay about farming technology, and then the author suddenly pivots to talking about the supermarket supply chain, you could probably see the tenuous connection, but you would be lost as to the main thesis of the author’s argument.

Don’t make your PDCA cycle difficult to follow by jumping all over the place from topic to topic – logically follow the continuation of the planning stage and refer back often to your map of the whole cycle.

Step 3: Check

The third stage of the PDCA cycle is to “check” the results of the “doing” that occurred in the second stage. Deming is credited with calling the third step “study” instead of “check,” but both are appropriate depending on the type of process improvement at hand.

The purpose of this step is to validate the resulting data from your process experimentation. This can be done in a few different ways:

- Hiring a third party to audit the new process, checking for any gaps

- Repeating the experimental process under similar conditions to ensure that it is reliably effective

- Repeating the experimental process under different conditions to test the limits of the process’ effects

- Expanding the scope and participation of the process to test its scalability

- Comparing own data with peer-reviewed studies that have proven results

There are even more ways of “checking” your data, so make sure to ask broad questions of which datasets will be quantified – and how – within your planning section.

Step 4: Act

The fourth step, "Act", actually has twofold importance: implementing the tested and approved change, and then also establishing long-term monitoring of that change.

Remember: the whole point of incremental change by using the PDCA cycle is continuous improvement – once your process has begun to improve, you want to implement standards that maintain that standard of improvement overall, so that you can move on to the next process improvement in your to-do list.

Don’t be that manager who preemptively concludes the cycle! After all, the reason why your team is so painstakingly going through the stages of the PDCA cycle is because they want to do it right the first time, and have the process be self-sufficient over time.

Benefits of Using the PDCA Cycle

The PDCA is nearly universal in application, whether you’re using it as a tool for kaizen in an assembly line or for re-distributing responsibilities among departments or even for experimenting with new standards yet to be implemented.

Here are just some of the observable benefits:

- Helps leadership break out of periods of stagnancy

- Promotes culture of pursuit of improvement

- Clarifies upcoming tasks for ongoing projects

- Creates standardization of small-scale testing before making big changes

- Promotes innovation

- Encourages creative problem-solving and practical solutions

Closing the PDCA Loop: What Comes Next?

A PDCA loop should refer to a single project; separate cycles for each project allow for ease of dividing tasks and monitoring progress.

However, we all relish the feeling of finally checking something off the never-ending to-do list, and there’s a temptation to abandon the new and improved production process because it has “been fixed” through the PDCA method.

Continuous improvement never ends! That’s why it’s so important to implement checks and balances to monitor the new process as others are eventually targeted. It’s more than a system – it’s a cycle! By dividing large processes into smaller stages of planning and testing and checkups, maintaining beneficial change can be manageable and easy enough to track.